Humidity Test Chamber

Humidity test chamber is a controlled environment system used to simulate various levels of humidity and temperature for testing purposes. These chambers are commonly employed in industries such as electronics, pharmaceuticals, automotive, research and development and materials science to evaluate the effects of humidity on products or materials. Humidity test chambers find applications across various industries where the effects of humidity on products, materials, and components need to be evaluated. Test Chamber Hub provides a comprehensive range of standard and custom-designed humidity test chambers suitable for various testing applications and requirements across industries.

APPLICATIONS OF HUMIDITY TEST CHAMBERS:

- Product Testing: Assessing the durability and performance of consumer electronics, appliances, textiles, and other consumer goods under humid conditions to ensure quality and reliability

- Packaging Testing: Testing packaging materials and containers for food, beverages, and consumer products to evaluate moisture resistance and shelf-life preservation.

- Electronics: Testing electronic components and devices for reliability under high humidity conditions.

- Pharmaceuticals and Life Sciences: Assessing the stability of vaccines, biological samples, drugs and pharmaceutical products in humid environments.

- Automotive: Evaluating the durability of automotive components under humid conditions.

- Materials Science: Testing and studying the effects of humidity on various materials such as plastics, metals, polymers, ceramics and composites.

- Research and Development: Supporting research and development efforts in environmental science, climate studies, and renewable energy by simulating specific humidity conditions for experimentation and testing.

DESIGN & SPECIFICATIONS OF OUR HUMIDITY TEST CHAMBERS:

- Material: Typically made of stainless steel for durability and resistance to corrosion.

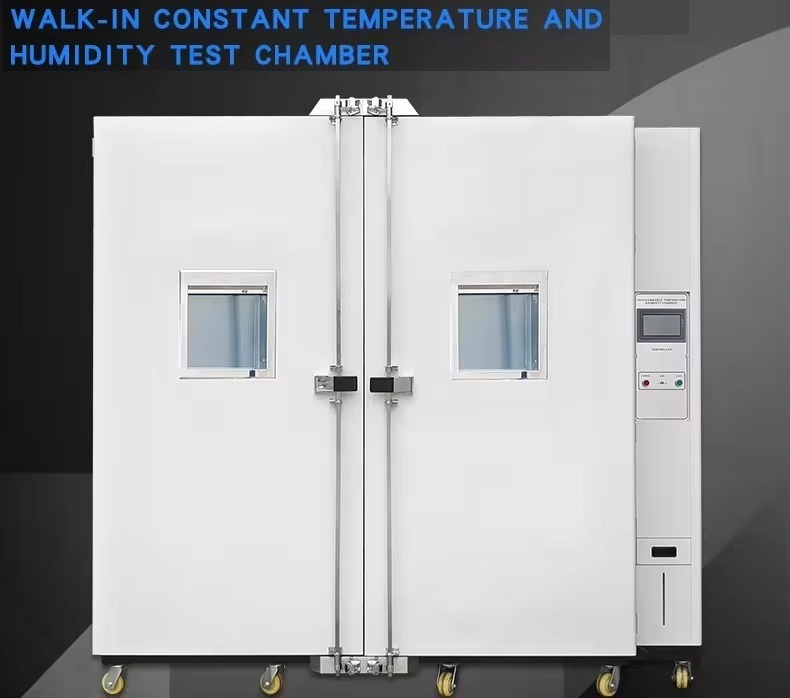

- Size: Available in various sizes to accommodate different testing needs, ranging from benchtop units to walk-in chambers.

- Sealing: Airtight seals to prevent moisture leakage and maintain the desired humidity levels.

- Humidification Method: Options include steam generators, ultrasonic humidifiers, or desiccant systems.

- Dehumidification: Incorporates dehumidifiers or desiccants to remove excess moisture and maintain precise humidity levels.

- Control Range: Capable of adjusting humidity levels within a wide range, typically from 10% to 98% relative humidity (RH) or higher.

- Accuracy: High-precision sensors and control systems to ensure accurate humidity control.

- Temperature Control Range: Capable of controlling temperature within a specified range, commonly from -40°C to 150°C or higher.

- Temperature Stability: Maintains temperature stability to within a narrow tolerance for consistent testing conditions.

- Programmability: Allows users to create and store test profiles with specific humidity and temperature conditions.

- User Interface: Intuitive interface for easy programming and monitoring of test parameters.

- Data Logging: Capability to log and export temperature and humidity data for analysis and documentation.

- Certification: Compliance with relevant industry standards and regulations, such as ISO, ASTM, or IEC standards.

- Calibration: Regular calibration of sensors and control systems to maintain accuracy and traceability.

- Customization: Options for customizing chamber design and features to meet specific testing requirements.

|

Temperature (& Humidity) Chamber |

Temperature & |

-20 to +100℃(-20 to +150℃-20 to +180℃) |

20 to 98%rh |

Type1 : 120L Type2 : 225L Type3 : 408L Type4 : 800L |

|

Low Temperature |

-40 to +100℃(-40 to +150℃-40 to +180℃) |

|||

|

Ultra-Low |

-70 to +100℃(-70 to +150℃-70 to +180℃*) |

Type2 : 306L

|

||

|

Basic Temperature

|

ambient temperature |

65 to 90%rh |

Type2 : 145L

|

|

|

+10 to +60℃ |

40 to 95%rh |

|||

|

Low Humidity Type |

-20 to +100℃ |

5 to 98%rh |

Type3 : 408L

|

|

|

Low Humidity Type |

-40 to +100℃ |

Type3 : 408L

|

||

|

Temperature Chamber |

Low Temperature Test |

-40 to +100℃ (-40 to +150℃ -40 to +180℃) |

|

Type1 : 120L Type2 : 225L Type3 : 408L Type4 : 800L |

|

Ultra-Low |

-70 to +100℃(-70 to +150℃-70 to +180℃*) |

Type2 : 306L Type4 : 800L |

Overview of Equipment :

The YH series is standard for reserach and testing of large specimens, assemblies and finished products such as avionics parts, Missiles parts, Rockets components, Lithium ion battery components, Electric vehicles powertrain & PV modules etc.

The right product that meets your standard reserach applications with many international testing standards like ISO, IEC, MIl & LV 124.

Features

- Standard and customized dimensions are available to fulfill your research based application.

- Safety is our priority and we follow all safety features for LiB tests.

- Finished product samples are possible to test in a single large chamber machine, no need to prepare semi finished or reduced size testing specimen.

- Electric vehicle modules durability & sustainability testing according to IEC & JIS international standards.

- Best buy for lithium ion battery charging and discharge with complete standard design.

Main specifications

|

Model |

YHU |

YHL |

YHG |

YHS |

|

Controlling system |

Uniform temperature control system |

Uniform temperature & humidity control system |

Uniform temperature control system |

Uniform temperature & humidity control system |

|

Temperature range |

-40°C ~ +180°C |

-40°C ~ +180°C |

-70°C ~ +180°C |

-70°C ~ +180°C |

|

Humidity range |

- |

20 ~ 95%rh |

- |

20 ~ 95%rh |

|

Temperature change rate (Reference example) |

-18°C ⇔ 158°C 3°C/min or more |

-45°C⇔155°C 3°C /min or more |

||

※Temperature change rate & dimensions are not correlated in terms of technical specification given above.

Standard Dimensions of Humidity Test Chamber

|

Model |

MARG - 1800 |

MARG - 2400 |

MARG - 3375 |

MARG - 4500 |

MARG - 8000 |

MARG - 11000 |

|

|

Chamber dimensions |

W(mm) |

1200 |

2000 |

1500 |

2000 |

2000 |

2500 |

|

H(mm) |

1000 |

1200 |

1500 |

1500 |

2000 |

2000 |

|

|

D(mm) |

1500 |

1000 |

1500 |

1500 |

2000 |

2200 |

|

|

Chamber Volume (L) |

1800 |

2400 |

3375 |

4500 |

8000 |

11000 |

|

Standard

- We are the leading manufacturer of Humidity and temperature test chamber in India and We can customize chamber size, temperture range, Humidity range & ramp rate according to our customers basic requirements.

- Humidity test chambers are designed according to the three basic standards. One is for thermal cycle test and follows IEC 61215 10.11 & JIS C 8990, second is for freezing performance test follows ICE 61215.10.12 & JIS 8990 and third is damp heating performance test IEC 61215 10,13 & JIS 8990.

- These big size chambers are designed to support DML testing follows IEC 61216 10.16 & JIS 8990 with the standard mechanical load testing.

Test Chamber Hub offers high-quality products, reliable customer support, and potentially customization options to suit your specific needs. To find out more about the Humidity Test Chamber, call us and contact us!